Fifth-generation fighter jets represent the pinnacle of modern air combat technology. Models such as the F-35 Lightning II, Su-57 Felon, and J-20 Mighty Dragon stand out with features like stealth, supercruise, and advanced sensor integration. However, producing the engines that power these aircraft remains one of the greatest challenges for the defense industry. Experts point out that the process of developing these engines can take years due to technical complexity, high costs, and international dependencies. In this report, we examine in detail the main challenges faced in producing fifth-generation fighter jet engines.

Technical Complexity and Performance Requirements

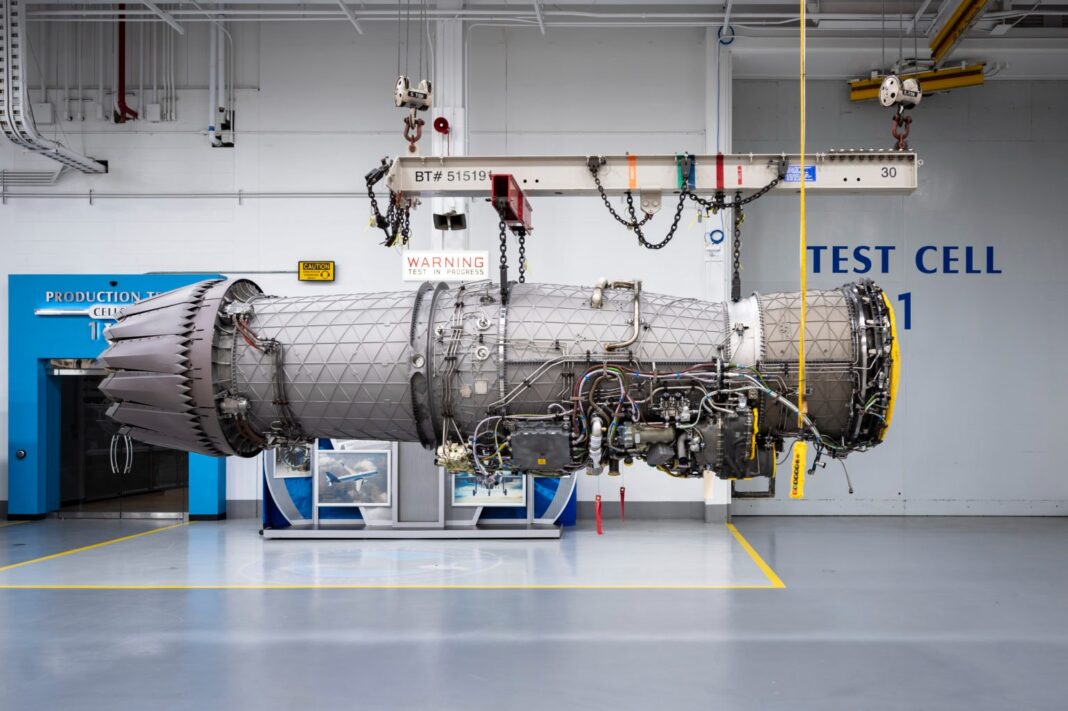

Fifth-generation fighter jet engines are far more demanding than conventional ones. These engines must not only deliver high thrust but also provide low fuel consumption, long lifespan, and reduced maintenance costs. For example, the Pratt & Whitney F135 engine developed for the U.S. F-35 program performs additional functions such as electrical power generation and cooling. This requires advanced thermal management systems to prevent overheating.

However, developing such engines can take 10–15 years—a duration often insufficient for responding quickly to emerging threats.

Another challenge lies in compatibility with stealth technology. Engines must be designed to minimize infrared (IR) signatures; otherwise, aircraft become vulnerable to radar and heat-seeking missiles. Projects like China’s WS-15 have faced production delays due to reliability issues. Experts note that China’s continued reliance on Russian engines hampers its ability to run a fully independent fifth-generation fighter program. Similarly, Russia’s Su-57 engine, the Izdeliye 30, struggles to achieve its targeted 176 kN thrust and remains limited in production—fewer than 30 aircraft have been built so far.

Innovations such as adaptive cycle engines aim to improve fuel efficiency by 35% and the power-to-weight ratio by 80%, yet integrating these technologies poses major challenges in materials science and aerodynamics. High-temperature-resistant ceramic matrix composites and 3D printing are employed, but mass production of these materials is expensive and time-consuming.

Cost and Industrial Constraints

Producing fifth-generation engines comes with astronomical costs. The U.S. F-35 program, which includes vertical take-off and landing capability, has reached a budget of over a trillion dollars—making it the most expensive aerospace project in history. Engine development constitutes a large portion of this cost; for example, the F-35’s engine is still undergoing development, and the U.S. Air Force now prefers upgrading existing cores instead of designing entirely new engines.

In countries like Russia and China, industrial infrastructure limitations stand out. Russia’s Su-57 program remains in an evaluation phase due to slow production rates and engine delays. China has made progress integrating the WS-10 engine into the J-20, but reliability issues have prevented it from reaching full operational capacity. These nations remain dependent on imports because of restricted access to Western technology; for example, China still uses Russian AL-31F engines.

Turkey is developing an indigenous engine for its fifth-generation KAAN fighter jet. As the second country within NATO to develop a fifth-generation fighter, Turkey has surprised the entire world, including its allies. The country plans to invest approximately $25 billion in the KAAN project, with $5 billion allocated specifically for the domestic engine—laying the foundation for an independent aviation industry. The KAAN program is progressing steadily. India and Turkey announced their fifth-generation fighter programs around the same time, but while Turkey has already completed the first flight and begun producing parts for the sixth aircraft, India has yet to move beyond the mock-up stage. For this reason, Turkey’s ability to produce both a fighter jet and its engine is considered more realistic. The Turks have proven time and again that when they say they will build something, they do it.

Geopolitical and Supply Chain Challenges

International sanctions and restrictions on technology transfer further complicate engine production. Competition between the U.S., Russia, and China prevents the sharing of critical engine technologies. For example, Russia’s fifth-generation programs, which have been ongoing since the 1980s, have slowed down due to economic sanctions. China’s J-20 is considered technologically incomplete and cannot reach its full potential due to engine-related issues.

In addition, there are challenges in maintenance and operational integration. Fifth-generation engines require systems such as sensor fusion and automatic target tracking. While these systems offer superior battlefield awareness—surpassing even AWACS aircraft—they also bring significantly higher maintenance costs.

Future Perspectives and Proposed Solutions

Experts suggest that overcoming these challenges will require international cooperation. For example, Japan’s partnership with Rolls-Royce for its F-3 program could accelerate technology transfer. The U.S., meanwhile, is focusing on adaptive engine technologies for its sixth-generation NGAD program, although the legacy of fifth-generation engines will continue to shape this transition.

In conclusion, producing a fifth-generation fighter jet engine is not only a technical challenge but also an economic, geopolitical, and industrial test. Nations are spending billions of dollars to achieve independence in this area, but success depends on innovative materials and faster development processes. Defense analysts predict that in the coming years, these technologies will evolve into sixth-generation aircraft, becoming even more complex than before.