The United States is entering a new phase of strengthening its ammunition production capacity amid an increasingly competitive and uncertain global security landscape. The goal is clear: to build a domestic, resilient, and scalable supply chain capable of surging production in times of crisis. Achieving this will require not only modernizing government facilities but also adopting new approaches that enhance speed, depth, and reliability.

At the core of the challenge lies the decline of America’s energetics industry — the backbone of propellant and explosive manufacturing. Years of underinvestment have left this sector fragile, with only a few plants struggling to meet global demand.

“Ammunition stockpiles aren’t just about numbers; they’re about the ability to sustain production under pressure,” said a U.S. industry representative. “The existing base was never built for today’s demand, and the gaps are becoming increasingly visible.”

The GOCO (Government-Owned, Contractor-Operated) plant model, once efficient for wartime mobilization, now shows structural weaknesses. Being tied almost entirely to government contracts limits flexibility and hampers the ability to compete in international markets. As a result, U.S. exports of 155mm artillery rounds remain far below those of allied producers.

A promising solution is the COCO (Commercially Owned, Commercially Operated) model — facilities built around vertically integrated supply chains that bring raw materials, energetics, and final assembly under one roof. This approach shortens production timelines, reduces dependencies, and increases surge capacity while fostering competitiveness beyond U.S. Army procurement.

South Korea’s experience demonstrates the model’s success. Decades of consistent investment have built a fully integrated ammunition industry capable of scaling rapidly in wartime. By 2024, South Korea had reached an annual capacity of around 250,000 rounds of 155mm artillery ammunition, the highest production level in the world.

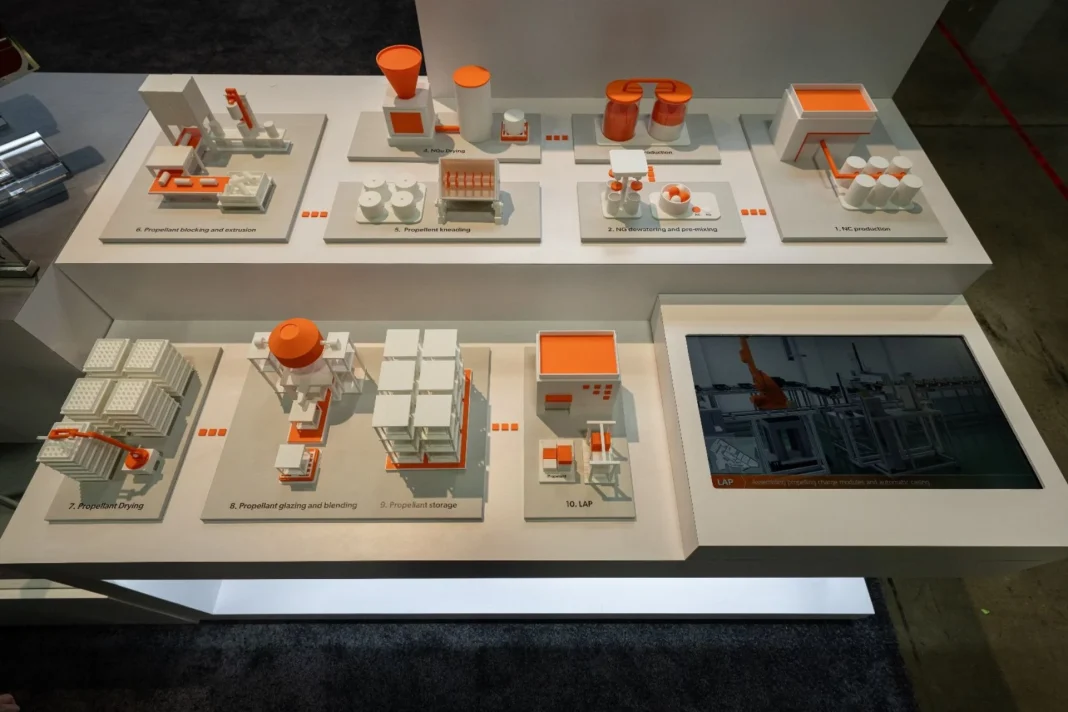

At the center of this achievement is Hanwha, South Korea’s leading defense manufacturer. The company operates one of the world’s few fully integrated energetics systems — managing everything from chemical inputs to final load-assemble-pack (LAP). This vertical integration delivers tighter quality control, faster throughput, and proven surge capability.

Hanwha’s strategy for the United States focuses on more than capacity. It emphasizes job creation, local integration, and alignment with U.S. industry and government partners. Such COCO facilities would not only ensure a steady supply to the U.S. Army but also boost export competitiveness and long-term industrial resilience.

“Investing in vertically integrated COCO facilities means addressing immediate defense needs while building lasting economic opportunities for American communities,” said Michael Coulter, President and CEO of Hanwha Global Defense. “This partnership model shows how allies can combine strengths to deliver both security and prosperity. Hanwha is ready to be part of that solution.”